Military-Steel

AMD Corp. is currently offering the production technologies and US patents of Military-Steel for sale or licensing.

Military-Steel is a low cost substitution of the USAF-96 steel and it can be utilized as a material for the cases of bunker buster bombs (penetrators). Other applications of Military-Steel include but are not limited to a material for armor plates and a material for large caliber gun barrels.

Grade1 of Military-Steel: Material for Cases of Deep Penetrating Bombs (Penetrators)

The U.S. Air Force is moving ahead with a new 2000-lb class bunker-buster bomb filled with 530 lbs of explosive material, built around an improved warhead called the BLU-137, which has a steel case made from the commercial USAF-96 steel (US Air Force, USA). The proposed Military-Steel is a high strength substitution of USAF-96 steel at the same ductility and toughness.

Another advantage of Military-Steel is its lower cost of raw materials due to lower concentrations of expensive elements. Table 1 shows the chemical compositions (%, wt.) and the cost of raw materials (%) of Military-Steel and the USAF-96 steel, wherein the cost of USAF-96 steel is 100%.

Table 1

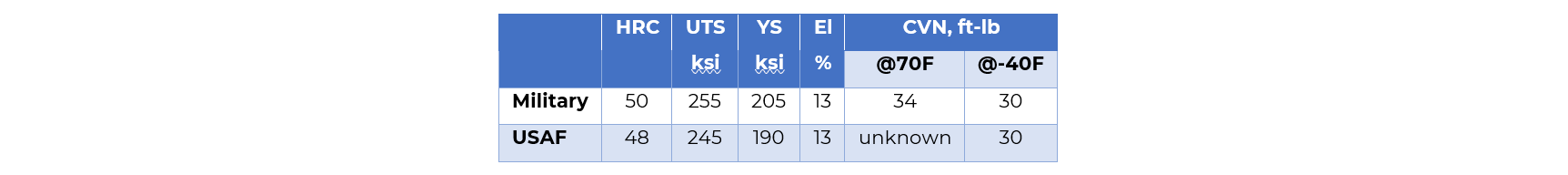

Table 2 below shows the ASTM standard tensile test results of the air melted quenched and low tempered Military-Steel and USAF-96 steel.

Table 2

wherein: HRC is Rockwell hardness scale C; UTS is ultimate tensile strength; YS is yield strength; El is total elongation; and CVN is Charpy v-notch

impact toughness energy in the longitudinal direction and at 70F and -40F.

Military-Steel exhibits a ~10% increase in yield and tensile strength when strain rates are increased from quasi-static to 200 1/s. The tensile and yield strengths at high strain rates will be referred to as the dynamic tensile and yield strength.

Military-Steel is superior to USAF-96 steel due to:

- Hardness and strength at the same ductility and toughness

- Reduction in total raw material cost by more than 25% through lower concentrations of Mo and Cr

- Better formability at hot working and better machinability.

Grade2 of Military-Steel: Material for Armor Plates

Military-Steel is a wrought Cr-V specialty steel for armor plates. The balanced compositions of Military-Steel supply higher strength and impact toughness relative to commercial steels.

Table 3 shows the chemical compositions (%, wt.) and a cost of raw materials (%) of Military-Steel and the commercial (Allegheny Technologies Inc., USA), wherein the cost of raw materials of the ATI-500 MIL steel is 100%.

Table 3

Balance - Fe and inevitable impurities.

Cost of raw materials of Military-Steel is 35% less than the cost of ATI-500 MIL steel, while cost of melting, hot rolling, and heat treatment are the same.

Table 4 shows a comparison of the ASTM standard mechanical properties of the water quenched and low tempered Military-Steel and the

mechanical properties of the hardened to optimum strength vs. toughness properties of ATI-500 MIL steel.

Table 4

Physical properties of Military-Steel are as follows:

-Density – 0.282 lbs./in3

-Thermal expansion coefficient – 6.5x10-6 at 70-220℉

Fabrication of armor vehicle parts from plates of Military-Steel include the following:

-Abrasive, water-jet, and saw cutting

-Thermal cutting methods such as plasma, laser, and torch cutting.

Drilling and machining of Military-Steel is similar to the machining of 4130 steel.

Hot forming of Military-Steel can be performed without any restrictions.

Military-Steel can be welded by standard techniques.

Grade3 of Military-Steel: Material for Large Caliber Gun Barrels

Military-Steel is a suitable material for large caliber gun barrels and accessories such as breech rings, breech blocks, muzzle bakers, etc.

Table 5 shows a comparison of concentrations of elements (%, wt.) and a cost of raw materials (%) of Military-Steel and the commercial CLARMHB7

steel (Aubert & Duval, France), wherein the cost of raw materials of CLARMHB7 steel is 100%.

Table 5

Table 6 shows the ASTM standard mechanical properties of the quenched and tempered at 1100℉ Military-Steel and the quenched and tempered at 1040℉ CLARMHB3 steel.

Table 6

Military-Steel is a material for large caliber gun barrels and accessories such as breech rings, breech blocks, muzzle bakers, etc.

After quenching and tempering at 1100℉, Military-Steel possesses high strength and high impact toughness.

*****

AMD Corp. is currently offering the production technologies and US patents of Military-Steel for sale or licensing

We invite the interested parties to contact us to discuss sale or licensing opportunities